- Product details

- Washing instruction

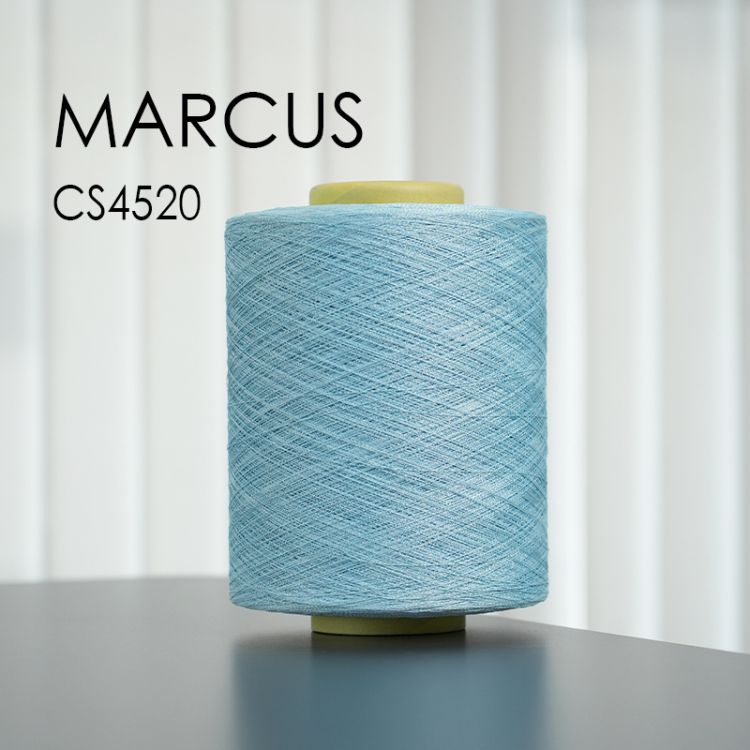

1/16NM 73 PAPER 27 POLYESTER

CS4520

应用

1. 12 针横机,1 根进线

2. 克重:260克/平方米

3. 抗起球标准:7200转(相同花型.针型.张力)为3级

4. 染色工艺:绞纱染色

5. 起订量:样纱10kg/色

APPLICATION

1. Flat Knitting machines 12 gauge 1 ply

2. Weight per square meter:gr260(on collection fabric on jersey stitch)

3. Pilling grade:3:has been tested on the collection swatch(same stitch/gauge/tension)according to Pilling box(ISO 12945-1/GB/T4802.3) at 7200 turns

4. DYEING PROCESS:Yarn dye

5. MINIMUN:The minimum for yarn dye is 10kgs(sample).

织造:

1.纱线已打蜡,尽量不回倒,若必须回倒,联系技术部。

2.织造时需保持65%的相对湿度,以确保织造顺利进行。

3.每只纱筒含5-6处手工结头,织片换筒时需将结头感应归边处理。

4.此组纱织片是AB色效果,不建议织复杂花型

5.收货后先试织,若有质量问题,15天内反馈。质量问题仅承担同等数量纱线,不负责面料织造和交货期费用。

6.织造时,损耗率8%,涵盖粗细不匀、色差、色花等导致的损耗。

KNITTING:

1:The yarn has been waxed. Try to avoid rewinding it.If rewinding is necessary, please contact the Technical Department.

2:During the knitting process, a relative humidity of 65% should be maintained to ensure the smooth progress of knitting.

3:Each yarn cone contains 5–6 manual knots, and the knots shall be edge-aligned by sensor detection during cone changing in weaving.

4:This set of yarn pieces has an AB color effect. It is not recommended to knit complex patterns

5:After receiving the goods, please try knitting first. If there are any quality issues, please provide feedback within 15 days. For quality issues, we only cover the same amount of yarn and do not take responsibility for fabric weaving or delivery period costs.

6:During the knitting process,the loss rate is 8%,which includes the losses caused by uneven thickness,color difference,uneven dyeing,etc.

工业洗涤指示:

1:40℃以下温水洗涤,加柔软剂,浸泡10-15分钟。

2:熨烫温度小于110℃。

3:滚动烘干温度60℃~80℃

4:不可氯漂。

5:不同洗衣机机型可能导致效果略有差异,请根据自身需求的状态调整洗涤方法

WASHING INSTRUCTION:

1:Wash in water under 40°C with softener, soak for 10-15 mins.

2:Iron at a maximum sole-plate temperature of 110℃.

3:Tumble dry on 60℃~80℃,

4:Cannot be chlorine bleached.

5:Slight variations in results may occur with different washing machine models. Please adjust the washing method according to your specific needs and fabric conditions.

| COLOR FASTNESS(Average) | LIGHT COLOUR | SMEDIUM COLOUR | DARK COLOURS | Standard | |||

|---|---|---|---|---|---|---|---|

| Change | Stain | Change | Stain | Change | Stain | ||

| Dry cleaning | 4 | 4 | 4 | 4 | 4 | 3-4 | ISO 105 D01/GB/T 5711 |

| Acid perspiration | 4 | 4 | 4 | 4 | 4 | 3-4 | ISO 104 E04/GB/T 3922 |

| Alkaline perspiration | 4 | 4 | 4 | 4 | 4 | 3-4 | ISO 104 E04/GB/T 3922 |

| Washing | 4 | 4 | 4 | 4 | 3-4 | ISO 105 C06/GB/T 12490 | |

| Dry rubbing | 4 | 4 | 4 | ISO 105 X12/GB/T 3920 | |||

| Wet rubbing | 4 | 4 | 3 | ISO 105 X12/GB/T 3920 | |||

| Light (except white color) | 4 | 3-4 | 4 | ISO 105 B02/GB/T 8427 | |||

For above points marked by *,to refer to OEKO-TEX STANDARD 100 requirements

Above data are average values coming from tests carried out in our laboratories