- Product details

- Washing instruction

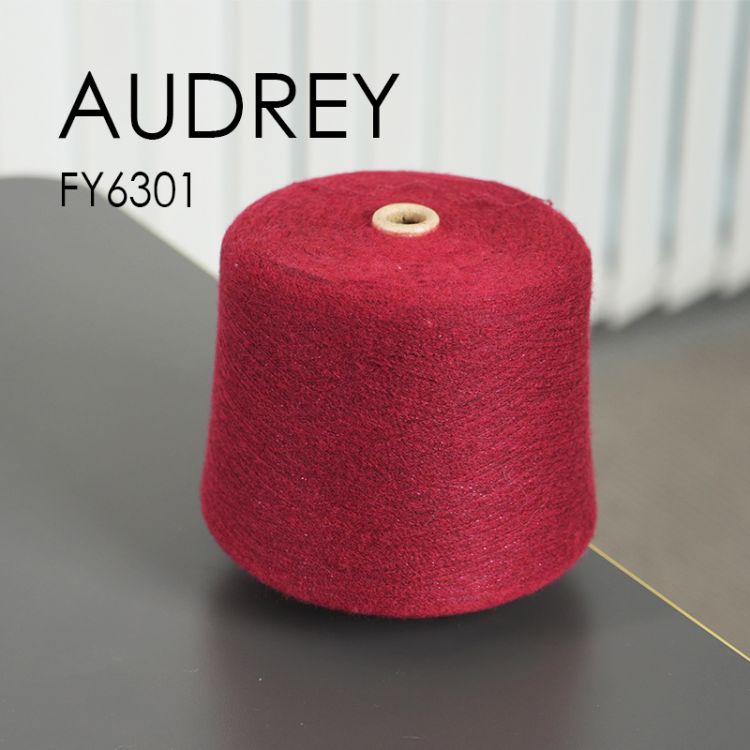

1/22NM 67%MERCERIZED WOOL15%NYLON10%POLY8%Lurex

FY6301

22000NM

应用

1跟进线 12针横机

染色方法

散毛染色

特别说明

1:30℃以下温水洗涤,加柔软剂,浸泡10-15分钟。2:滚动烘干温度60℃~80℃

3:熨烫温度小于110℃ 4:不可氯漂。5:纱线已打蜡,尽量不回倒,若必须回倒,联系技术部。损耗率10%。

6:注意在洗涤过程不宜偏酸或偏碱,pH值:6.5-8左右,金银丝遇酸碱会变色。

7:每个纱筒有15个手工结,织造请开启小接头探测器并归边;换筒首尾各拉2米,打结后归边防接头两侧异常.

APPLICATION

Flat knitting machines 12 gauge 1 ply

Weight per square meter: gr188 (on collection fabric on jersey stitch)

PILLING

Pilling grade: 3-4 :has been tested on the collection swatch (same stitch/gauge/tension)

according to Pilling box(ISO 12945-1/GB/T 4802.3) at 7200 turns

DYEING PROCESS

Fibre dye only

BEST DYE-LOT

MINIMUM

The minimum for Fibre dye is 50kgs(sample) and 300kgs(bulk) per colour.

CARE INSTRUCTIONS

1: We suggest finishing in water at 30℃ for 10-15 minutes with softener of Non-ionic/Weak cationic.2: Tumble dry on 60℃- 80℃.

3: Iron at a maximum sole-plate temperature of 110℃ 4: Cannot be chlorine bleached.5:The yarn has been waxed.Try to avoid rewinding it.

If rewinding is necessary, please contact the Technical Department.The waste of 10% due to the characteristics of the yarn.

6:Avoid acidic or alkaline wash pH 6.5-8.Metallic discolors upon exposure to acids/bases.

7:Each yarn cone has 15 hand - knotted areas. When knitting, please turn on the small joint detector and trim the edges. When changing

FASTNESS

| Shade change | Stain change | Standard | |

|---|---|---|---|

| Dry cleaning | 3 | 2-3 | ISO 105 D01/GB/T 5711 |

| Acid perspiration * | 3 | 3 | ISO 104 E04/GB/T 3922 |

| Alkaline perspiration * | 3 | 3 | ISO 104 E04/GB/T 3922 |

| Washing | 3-4 | 3 | ISO 105 C06/GB/T 12490 |

| Dry rubbing * | 3-4 | ISO 105 X12/GB/T 3920 | |

| Wet rubbing | 2-3 | ISO 105 X12/GB/T 3920 | |

| Light (except white color) | 3-4 | ISO 105 B02/GB/T 8427 | |

| Water | 3 | 3 | ISO 105 E01/GB/T 5713 |

For above points marked by *,to refer to OEKO-TEX STANDARD 100 requirements

Above data are average values coming from tests carried out in our laboratories