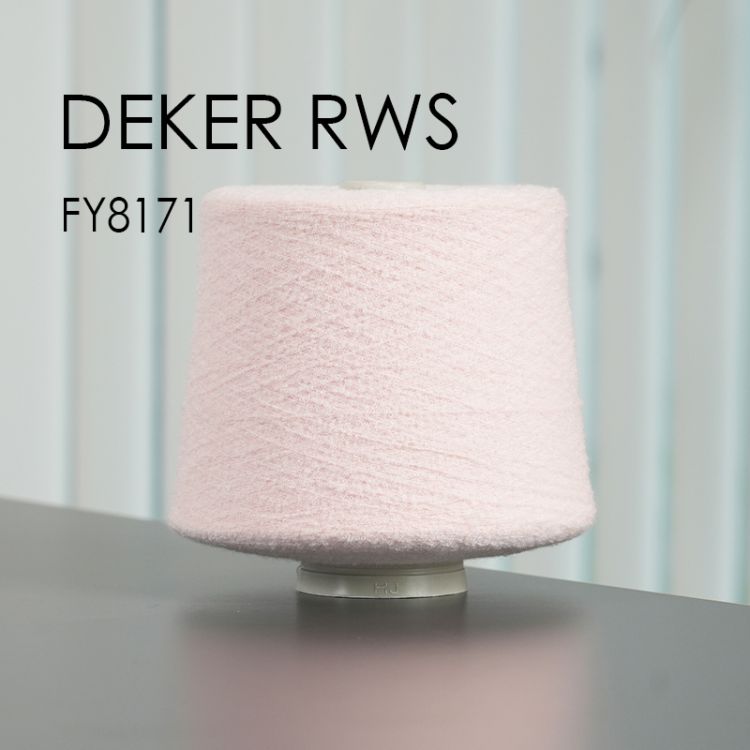

- Product details

- Washing instruction

1/16NM 47%MERCERIZED WOOL 31%ACRYLIC 22%NYLON

FY8171

16000NM

应用

1跟进线 12针横机

染色方法

绞纱染色

特别说明

1:30℃以下温水洗涤,加柔软剂,浸泡10-15分钟。2:滚动烘干温度60℃~80℃。

3:熨烫温度小于110℃。 4:不可氯漂。5:存放时间最好不要超过三个月,否则弹性会改变

6:纱线已打蜡,尽量不回倒,若必须回倒,联系技术部。

7:圈圈纱织片留意密度及张力不宜太紧,否则易造成圈圈滑移。换筒时请将纱筒头,尾各拉掉1M。

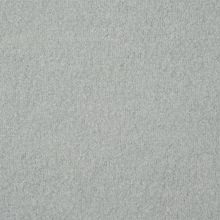

APPLICATION

Flat knitting machines 12 gauge 1 ply

Weight per square meter: gr240 (on collection fabric on jersey stitch)

PILLING

Pilling grade: 3 :has been tested on the collection swatch (same stitch/gauge/tension)

according to Pilling box(ISO 12945-1/GB/T 4802.3) at 7200 turns

DYEING PROCESS

Yarn dye only

BEST DYE-LOT

The minimum for RW is 200kg ; The minimum for yarn dye is 6kgs

MINIMUM

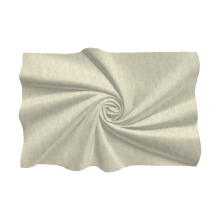

CARE INSTRUCTIONS

1: We recommend treating sweater in lukewarm water(max.30℃) finishing for 10-15minutes with softener of Non-ionic/weak cationic.

2:Tumble dry on 60℃- 80℃.3:Iron at a maximum sole-plate temperature of 110℃ 4:Cannot be chlorine bleached.5:Do not stock more than 3

months,otherwise the elasticity will be changed.6:The yarn has been waxed. Try to avoid rewinding it.If rewinding is necessary,please

contact the Technical Department.7:Pay attention to stitch density and tension when knitting with loop yarn;avoid excessive tightness,as

it may cause loop slippage.When changing spools,ensure to discard the first and last meter of yarn from each end.8:For finished garments,

FASTNESS

| Shade change | Stain change | Standard | |

|---|---|---|---|

| Dry cleaning | 3-4 | 3 | ISO 105 D01/GB/T 5711 |

| Acid perspiration * | 3-4 | 3 | ISO 104 E04/GB/T 3922 |

| Alkaline perspiration * | 3-4 | 3 | ISO 104 E04/GB/T 3922 |

| Washing | 3-4 | 3 | ISO 105 C06/GB/T 12490 |

| Dry rubbing * | 3-4 | ISO 105 X12/GB/T 3920 | |

| Wet rubbing | 3 | ISO 105 X12/GB/T 3920 | |

| Light (except white color) | 3-4 | ISO 105 B02/GB/T 8427 | |

| Water | 3-4 | 3 | ISO 105 E01/GB/T 5713 |

For above points marked by *,to refer to OEKO-TEX STANDARD 100 requirements

Above data are average values coming from tests carried out in our laboratories